A winch solenoid is a key part of a winch system. It controls the power flow to the winch motor.

Understanding how a winch solenoid works can help ensure your winch operates smoothly and safely. The solenoid acts as a switch, controlling the electrical current from the battery to the winch motor. When activated, it allows the current to flow, powering the winch to pull or lift heavy loads.

Without a properly functioning solenoid, the winch might not perform efficiently, or at all. This guide will explain the basics of winch solenoids, their importance, and how they function. By the end, you’ll have a clear understanding of this vital component and its role in your winch system.

Introduction To Winch Solenoids

Winch solenoids play a crucial role in the operation of winches. They act as the control center, ensuring smooth and reliable performance. For off-road enthusiasts, understanding winch solenoids can enhance the overall winching experience. Knowing how they work is essential for safe and efficient off-roading adventures.

Importance For Off-roaders

Off-roaders often find themselves in challenging terrains. A winch is a vital tool in these situations. It helps in getting unstuck from mud, snow, or rocky paths. The winch solenoid is the heart of this tool. It controls the flow of electricity to the winch motor. Without a functioning solenoid, the winch won’t work correctly. Thus, its importance cannot be overstated.

Basic Functionality

The basic function of a winch solenoid is to direct power from the battery to the winch motor. It acts as a switch, opening and closing the circuit. When you press the winch control button, the solenoid activates. This allows electrical current to flow through, powering the winch motor. The motor then pulls or releases the winch cable as needed.

Winch solenoids are designed to handle high current loads. They ensure that the winch operates efficiently without overheating. A quality solenoid enhances the durability and reliability of the winch system. Understanding these basics helps in troubleshooting and maintaining your winch.

Credit: forum.ih8mud.com

Components Of A Winch Solenoid

Understanding the components of a winch solenoid is crucial. It helps in knowing how this essential device operates. A winch solenoid controls the electrical current that powers the winch motor. Below we discuss the main parts and material considerations for a winch solenoid.

Main Parts

A winch solenoid comprises several key parts. These parts work together to control the winch’s function. Let’s look at them in detail.

- Coil: The coil creates the magnetic field. This field is vital for the solenoid’s operation.

- Plunger: The plunger moves inside the coil. It helps in controlling the electrical circuit.

- Contacts: These allow electrical current to flow when the solenoid is activated.

- Housing: The housing protects internal components. It ensures the solenoid’s durability.

Material Considerations

Choosing the right materials for each part is important. It affects the solenoid’s performance and lifespan.

| Component | Material | Reason |

|---|---|---|

| Coil | Copper | Copper is highly conductive. |

| Plunger | Steel | Steel is strong and durable. |

| Contacts | Silver | Silver resists corrosion and ensures good conductivity. |

| Housing | Plastic or Metal | Provides protection and structural integrity. |

By understanding these components and their materials, you can better appreciate how a winch solenoid works. This knowledge ensures that you choose the right solenoid for your needs.

How A Winch Solenoid Operates

A winch solenoid plays a crucial role in the operation of a winch. It acts as a switch to control the power from the battery to the winch motor. Understanding how a winch solenoid operates can help in troubleshooting and maintenance.

Engaging The Winch

Engaging the winch starts with activating the winch solenoid. This involves sending a small electrical current to the solenoid coil. The coil then creates a magnetic field. This magnetic field pulls a metal contactor, completing the circuit.

Once the circuit is complete, power flows from the battery to the winch motor. The motor then begins to pull in the winch line. This process allows the winch to lift or pull heavy loads. The solenoid ensures that the winch motor only operates when needed.

Disengaging The Winch

Disengaging the winch is just as important as engaging it. To disengage, the electrical current to the solenoid coil is stopped. This causes the magnetic field to collapse. Without the magnetic field, the metal contactor returns to its original position.

In this position, the circuit is broken, and power no longer flows to the winch motor. The motor stops, and the winch line remains in place. This process ensures that the winch does not operate continuously, preventing overheating and damage.

Electrical Connections

Understanding the electrical connections of a winch solenoid is key to its proper operation. The solenoid acts as a switch, directing power from the battery to the winch motor. This process involves several important connections that ensure the system works smoothly.

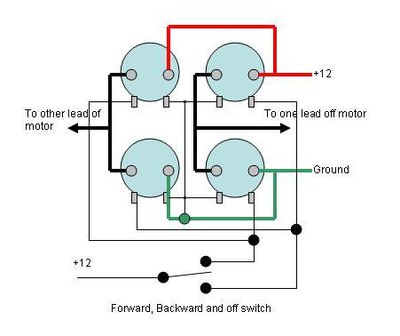

Wiring Diagrams

Wiring diagrams are essential for setting up the electrical connections correctly. These diagrams illustrate how to connect each wire to its respective terminal. Here is a simple wiring diagram for a winch solenoid:

| Terminal | Connection |

|---|---|

| Battery Positive (+) | Connect to the positive terminal of the battery |

| Battery Negative (-) | Connect to the negative terminal of the battery |

| Winch Motor | Connect to the winch motor terminals |

| Control Switch | Connect to the winch control switch |

Follow these connections to ensure the winch solenoid functions properly. Incorrect wiring can lead to failures or damage to the system.

Safety Precautions

When working with electrical connections, safety is crucial. Follow these safety precautions:

- Always disconnect the battery before starting.

- Use insulated tools to prevent short circuits.

- Check all connections twice before powering up.

- Wear protective gear, such as gloves and goggles.

Adhering to these precautions will help prevent accidents and ensure a safe installation process.

Common Issues And Troubleshooting

Understanding how to identify and fix common winch solenoid issues is crucial for maintaining its performance. This section highlights typical problems you may encounter and provides straightforward solutions to get your winch working again.

Identifying Problems

Common issues with winch solenoids can range from electrical faults to mechanical wear. Identifying the root cause is the first step in troubleshooting.

- Electrical faults: These include blown fuses, corroded connections, and faulty wiring.

- Mechanical wear: This can be due to worn-out parts, rust, or dirt accumulation.

Symptoms of these issues might include a non-responsive winch, intermittent operation, or unusual noises.

Basic Fixes

After identifying the problem, applying basic fixes can often resolve it. Here are some common solutions:

- Check the power source: Ensure the battery is fully charged and the connections are secure.

- Inspect the wiring: Look for any frayed wires or loose connections.

- Clean the connections: Remove any rust or dirt from the terminals.

For electrical faults, use a multimeter to check the voltage at different points. This can help pinpoint where the issue lies. A table can be useful for this:

| Component | Expected Voltage | Action if Faulty |

|---|---|---|

| Battery | 12V | Charge or replace battery |

| Solenoid Terminals | 12V | Clean or replace terminals |

| Control Switch | 12V | Inspect switch wiring |

For mechanical wear, regular maintenance can prevent many issues. Lubricate moving parts, replace worn-out components, and keep the winch clean.

Maintaining Your Winch Solenoid

Maintaining your winch solenoid is essential for its proper functioning. Neglecting maintenance can lead to failures and costly repairs. By following simple steps, you can extend the life of your winch solenoid.

Regular Checks

Regular checks help spot potential issues early. Inspect the solenoid and its connections. Look for signs of wear, corrosion, or loose wires.

- Check the electrical connections.

- Ensure there is no corrosion.

- Verify the tightness of all bolts and nuts.

Use a multimeter to test the continuity. This ensures the solenoid is working correctly. Regular checks prevent unexpected failures.

Cleaning And Lubrication

Cleaning and lubrication are crucial for maintaining your winch solenoid. Dirt and grime can cause malfunctions. Clean the solenoid with a soft brush and mild cleaner.

- Disconnect the power supply.

- Remove dirt using a soft brush.

- Wipe with a damp cloth.

- Ensure the solenoid is dry before reconnecting.

Lubrication is also important. Use a light lubricant on moving parts. This reduces friction and wear. Lubricate the solenoid twice a year.

Maintaining your winch solenoid keeps your equipment reliable. Follow these steps to ensure longevity and performance.

Choosing The Right Winch Solenoid

Choosing the right winch solenoid can be a daunting task. A winch solenoid is crucial for your winch system’s functionality and safety. It controls the high current flow to the winch motor, ensuring smooth operations. To make the best choice, consider compatibility and performance factors.

Compatibility

Ensure the solenoid is compatible with your winch model. Check the voltage requirements. Most winches operate on 12V or 24V systems. Verify the solenoid matches these specifications. Also, look at the solenoid’s current rating. This should match or exceed your winch’s motor current draw. Check your winch manual for exact figures.

Performance Factors

Consider the solenoid’s durability. Look for weather-resistant models. These solenoids withstand harsh conditions better. Heat resistance is also important. A good solenoid should handle high current loads without overheating. Look for solenoids with a high duty cycle. This indicates they can operate longer without failure.

Another factor is the solenoid’s response time. Quick response times mean better control over the winch. Choose solenoids from reputable brands. This ensures quality and reliable performance. Read user reviews to gauge real-world performance. A well-chosen solenoid enhances your winch’s efficiency and lifespan.

Credit: www.offroadsc.com

Installation Tips

Installing a winch solenoid may seem challenging, but it’s easier with the right tips. The solenoid plays a key role in your winch system, so proper installation is crucial. Follow these steps to ensure a smooth and successful setup.

Step-by-step Guide

First, disconnect the vehicle’s battery. Safety comes first. Locate the winch and find the solenoid mounting spot. It should be close to the winch motor. Attach the solenoid to this spot using bolts and screws.

Next, connect the cables. Start with the positive cable from the battery to the solenoid. Then, connect the positive cable from the solenoid to the winch motor. Attach the negative cable from the solenoid to the ground on the vehicle’s frame. Finally, connect the negative cable from the winch motor to the ground.

Double-check all connections. Ensure they are tight and secure. Reconnect the vehicle’s battery. Test the winch to make sure it works correctly. If it doesn’t, review your connections again.

Tools Needed

Gather these tools before starting:

- Wrench set

- Screwdriver

- Wire cutters

- Electrical tape

- Protective gloves

Having these tools on hand will make the installation smoother. Ensure you have everything before you start.

Advanced Tips For Off-roaders

Off-roading demands more than just a powerful vehicle and rugged terrain. It requires knowledge of every component that can make the ride smoother and safer. One crucial part is the winch solenoid. Understanding its workings and optimizing its performance can make a significant difference.

Enhancing Performance

To enhance winch solenoid performance, regular maintenance is key. Inspect connections for corrosion or damage. Clean contacts with a wire brush.

Use a multimeter to check the solenoid’s continuity. Ensure the voltage levels are within the recommended range. This prevents unexpected failures during critical moments.

Another tip is to use high-quality cables. Thick, well-insulated cables reduce resistance and improve power delivery. This results in smoother and more reliable winch operations.

Custom Modifications

Custom modifications can tailor the winch solenoid to specific needs. Installing a dual battery setup is beneficial. It provides extra power for the winch without draining the vehicle’s main battery.

Consider adding an in-cab winch control system. This allows you to operate the winch from inside the vehicle. It enhances safety and convenience.

Upgrading the solenoid to a sealed unit protects it from water and dust. This is crucial for off-roaders who frequently encounter harsh environments.

| Modification | Benefit |

|---|---|

| Dual Battery Setup | Provides extra power and prevents main battery drain |

| In-Cab Winch Control | Enhances safety and convenience |

| Sealed Solenoid Unit | Protects from water and dust |

By following these advanced tips, off-roaders can ensure their winch solenoid performs optimally. This makes off-roading safer and more enjoyable.

Credit: www.youtube.com

Frequently Asked Questions

What Is A Winch Solenoid?

A winch solenoid is an electrical switch that controls the power to the winch motor. It enables remote operation.

How Does A Winch Solenoid Work?

A winch solenoid works by using a small electric current to control a larger current. This activates the winch motor.

Why Is A Winch Solenoid Important?

A winch solenoid is important for safe and efficient winch operation. It prevents electrical overloads and allows remote control.

Can A Winch Operate Without A Solenoid?

No, a winch cannot operate without a solenoid. The solenoid is essential for controlling the winch motor’s power.

Conclusion

Understanding how a winch solenoid works is vital for safe operation. This small component controls your winch’s power. It ensures smooth and reliable performance. Remember to maintain your solenoid for optimal function. Regular checks can prevent potential issues. A functional solenoid keeps your winch ready for action.

Always consult your manual for specific guidance. Stay informed and stay safe while using your winch.