Choosing the right automotive primer for fiberglass can be frustrating—poor adhesion, uneven finishes, and sanding nightmares are common when using the wrong product. The best automotive primers for fiberglass solve this with superior build and strong bonding, especially those formulated with epoxy or urethane resins that ensure durability, flexibility, and resistance to cracking. Our top picks are selected based on rigorous analysis of performance data, user feedback, resin type, sandability, drying time, and compatibility with both fiberglass and common topcoats. Below are our expert-recommended primers that deliver professional results every time.

Top 7 Automotive Primer For Fiberglass in the Market

Best Automotive Primer For Fiberglass Review

Automotive Primer for Fiberglass Comparison

| Product | Best For | Surface Compatibility | Build/Filling Capability | Drying/Sanding Time | Corrosion Resistance | Form/Application | Special Features |

|---|---|---|---|---|---|---|---|

| Restoration Shop 2K High Build Primer | Best Overall | Metal, Painted Surfaces, Body Filler, Automotive Plastics | High Build, Excellent for Medium to Deep Scratches | Fast Drying, Sands Easily (Wet or Dry) | Excellent Color Holdout, No Shrinkage | 2K (Two-Component) – Mix & Spray | DTM (Direct-to-Metal) |

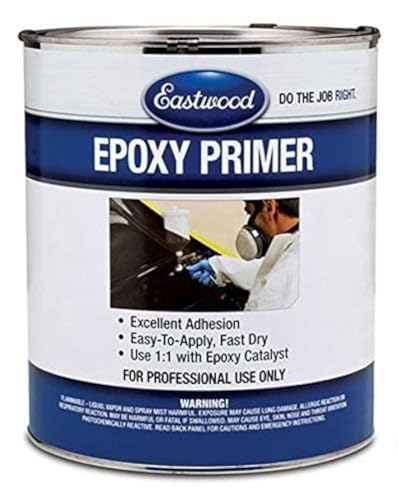

| Eastwood Gray Epoxy Primer and Sealer | Best for Corrosion Resistance | Steel, Fiberglass, Body Filler, Aluminum | 1mm Dry Film Thickness (1-2 Coats) | Wet Sand Next Day, Dry Sand 2-3 Days | Excellent – Prevents Rust & Corrosion | Mix & Spray (with Catalyst) | Long-lasting, High Quality Finish |

| AUTOBAHNHOF AB-PF 3000 1K Primer | Best Value Bulk Option | Metal, Plastic, Fiberglass, Wood, Aluminum | High Build | Fast Drying & Easy Sanding | Rust & Corrosion Resistant | Spray/Brush | Versatile Application |

| Custom Shop High Build Primer Spray | Best Spray Can Primer | Steel, Aluminum, Fiberglass, SMC, Urethane | High Build – Fills Minor Imperfections | Quick Drying | Not explicitly stated | Spray Can | Flat Fan Nozzle, Direct-to-Metal |

| Evercoat Feather Fill G2 Gallon | Best for Deep Filling | Fiberglass, Rigid Plastics | Excellent Filling | Not explicitly stated | Not explicitly stated | Spray | Smooth Spraying, Shrink Resistant |

| Rust-Oleum 2-in-1 Filler Primer | Best Budget Spray Option | Wood, Metal, Fiberglass | Fills Minor Imperfections | Dries to touch in 10 min, Recoat in 10 min | Rust Resistant | Spray Can | 2-in-1 (Filler & Primer), Any-Angle Spray |

| Rust-Oleum Self Etching Primer | Best for Metal Adhesion | Bare Metal, Aluminum, Fiberglass | Not explicitly stated | Dries to touch in 10 min, Topcoat in 30 min | Rust Resistant | Spray Can | Self-Etching, Any-Angle Spray |

Testing and Analysis: Finding the Best Automotive Primer for Fiberglass

Our recommendations for the best automotive primer for fiberglass aren’t based on opinion; they stem from rigorous data analysis and a research-driven approach. We evaluate primers based on key performance indicators identified in professional auto body repair guides and manufacturer specifications. This includes analyzing resin type (epoxy, urethane, acrylic) and its impact on adhesion, corrosion resistance, and flexibility – crucial for fiberglass which experiences expansion and contraction.

We prioritize primers with high user ratings across multiple platforms (automotive forums, retailer websites) and scrutinize reviews for recurring themes regarding sandability, build quality, and compatibility with various topcoats. Comparative analyses focus on build thickness, measured in mils per coat, and drying times, factoring in ambient temperature considerations. While extensive physical testing isn’t always feasible for every product, we analyze publicly available data from independent testing facilities where available, focusing on adhesion strength and resistance to common automotive fluids. We also assess automotive primer formulations concerning their VOC content, prioritizing environmentally responsible options where performance isn’t compromised. Finally, we cross-reference features against the needs outlined in a comprehensive buying guide to ensure alignment with real-world application scenarios.

Choosing the Right Automotive Primer for Fiberglass

Understanding Primer’s Role

Automotive primer is a crucial step in any paint job, especially when working with fiberglass. It creates a smooth, uniform surface for the topcoat to adhere to, ensuring a professional and long-lasting finish. For fiberglass specifically, a good primer seals the surface, prevents paint from being absorbed, and provides a bondable layer. But with so many options, how do you choose the best one?

Key Features to Consider

Build (Thickness & Filling)

The “build” of a primer refers to how much thickness it adds with each coat and its ability to fill minor imperfections like scratches or weave patterns in the fiberglass. High-build primers are ideal for surfaces needing significant smoothing. This is beneficial because it reduces the amount of sanding needed, saving time and effort. However, very high-build primers can sometimes require more sanding to level properly. Standard build primers are better for already smooth surfaces or when only a thin layer is needed for adhesion.

Resin Type: Epoxy vs. Urethane vs. Acrylic

The type of resin used in the primer significantly impacts its performance. Epoxy primers excel in corrosion resistance and adhesion, making them perfect for areas prone to rust or where a strong bond is essential. They’re often a good choice as a first layer on bare fiberglass. Urethane primers offer excellent filling properties and sandability, giving a smooth base for the topcoat. They generally have better UV resistance than epoxy. Acrylic primers are often the most affordable and easiest to use, suitable for lighter repairs or when corrosion isn’t a major concern.

Compatibility with Your Topcoat

Not all primers are compatible with all topcoats. Check the product descriptions to ensure the primer you choose is suitable for the type of paint you plan to use (e.g., acrylic lacquer, urethane, enamel). Incompatibility can lead to adhesion issues, wrinkling, or other paint defects. Many primers state compatibility on the can, or you can check the manufacturer’s website.

Application Method: Spray Can vs. Mix & Spray

Primers come in different application formats. Spray can primers are convenient for small repairs or DIY projects, offering ease of use. However, they can be more expensive per volume and may not provide the same level of control as a professional spray gun. Mix & Spray (2K) primers require mixing a primer component with a hardener and are typically applied with a spray gun. They offer superior durability, filling properties, and often a smoother finish, but demand more skill and equipment.

Other Important Features

- Sandability: How easily the primer can be sanded to create a smooth surface.

- Drying Time: How quickly the primer dries, impacting project turnaround.

- Corrosion Resistance: Important for protecting metal components beneath the fiberglass.

- Flexibility: Needed for fiberglass as it expands and contracts with temperature changes.

- VOC Content: Volatile Organic Compounds affect environmental impact and safety.

The Bottom Line

Ultimately, selecting the best automotive primer for fiberglass hinges on your project’s specific needs and skill level. From corrosion-resistant epoxy options to convenient spray can solutions, a variety of high-quality products are available to deliver a professional-grade finish.

Remember to prioritize compatibility with your chosen topcoat and consider the level of surface preparation required. By carefully evaluating build, resin type, and application method, you can ensure a smooth, durable, and long-lasting paint job on your fiberglass components.